This involves identifying areas for improvement in the production process and implementing changes Outsource Invoicing to reduce costs and increase efficiency. By continuously improving the production process, the overhead costs can be reduced, which can prevent underapplied overhead. Efficient use of resources is also important in preventing underapplied overhead. This can be achieved by reducing waste and inefficiencies in the production process.

Predetermined Overhead Rate Formula

Common examples of allocation bases include direct labor hours, machine hours, direct labor cost, or even units produced. The selection depends on the nature of the business and which predetermined overhead rates activity best drives the overhead costs. For a labor-intensive operation, direct labor hours might be most suitable, while a highly automated facility might find machine hours to be a more accurate measure. Estimating the total amount of the chosen allocation base for the upcoming period is also necessary, often based on production forecasts or historical activity levels.

Operating Expenses Vs Overhead Expenses

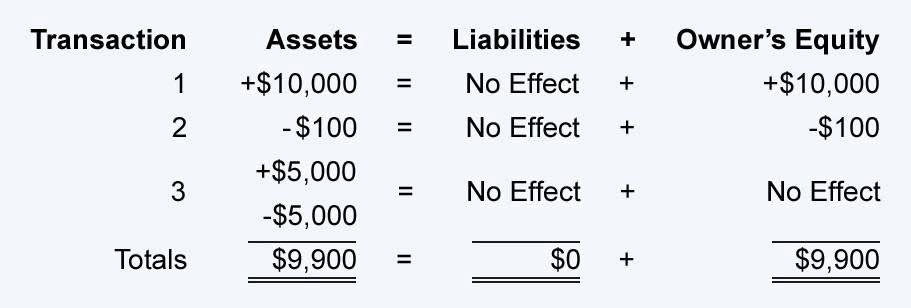

The predetermined rate usually be calculated at the beginning of the accounting period by relying on the management experience and prior year data. Predetermined overhead rate is the estimated overhead that will allocate to each product at the begining of accounting period. It is equal to the estimate overhead divided by the estimate production quantity. Traditionally, overheads have been absorbed in the product cost based on a single basis of apportionment. For instance, in a labor-intensive environment, labor hours were used to absorb overheads.

Formula:

Knowing the overhead cost per unit allows the business to set competitive pricing while still covering their indirect expenses. The activity base for applying manufacturing overhead is normally a unit quantity which relates to the manufacturing process such as the following. Hence, the fish-selling businesses need to monitor the seasonal variations and adjust the cost pattern of the products. The use of predetermined overheads effectively incorporates the cost effects of seasonal variations in the product cost and price.

Predetermined Overhead Rate (POR) Formula

By analyzing https://cisabfoundationgh.org/principles-and-concepts-of-accounting-fa2/ the overhead applied to similar jobs, management can identify patterns or anomalies in overhead consumption, which can lead to process improvements or cost-saving measures. This comparative analysis is an integral part of maintaining competitive pricing and operational efficiency. In these situations, a direct cost (labor) has been replaced by an overhead cost (e.g., depreciation on equipment).

Predetermined Overhead Rate Calculation (Step by Step)

- Many accountants always ask about specific time which we need to do this, at what point in time is the predetermined overhead rate calculated.

- The overhead rate is calculated by dividing total overhead costs by an appropriate allocation measure such as direct labor hours.

- The predetermined rate is based on estimates before the accounting period begins and is held constant throughout the period.

- Changes in the company’s operations or market conditions can affect the estimated total overhead costs, the estimated total amount of the allocation base, or the estimated level of activity.

- The immediate benefit is to assist with pricing, and to understand the margin on each product and sale.

Second, machines are less likely to require breaks or time off, which can affect the production schedule. Finally, using machine hours can provide a better measure of the actual usage of overhead costs, as the machines are the ones that consume the most energy, utilities, and maintenance costs. Cost accountants want to be able to estimate and allocate overhead costs like rent, utilities, and property taxes to the production processes that use these expenses indirectly.

- For example, a single plant-wide rate is easy to calculate but may not accurately reflect the overhead costs of each department.

- The selection depends on the nature of the business and which activity best drives the overhead costs.

- Calculating the predetermined overhead rate plays a pivotal role in cost accounting, providing a basis for allocating manufacturing overhead costs to products.

- In this article, we will discuss the formula for predetermined overhead rate and how to calculate it.

- Predetermined overhead rates are calculated estimations that factor the overhead into to total manufacturing cost-per-unit, for a specific period of time.

For example, if we choose the labor hours to be the basis then we will multiply the rate by the direct labor hours in each task during the manufacturing process. The predetermined overhead rate computed above is known as single or plant-wide overhead rate which is mostly used by small companies. In large ones, each production department computes its own rate to apply overhead cost. The use of multiple predetermined overhead rates may be a complex and time consuming task but is considered a more accurate approach than applying only a single plant-wide rate.

Importance of Accurate Predetermined Overhead Rate

The chosen activity base should have a logical cause-and-effect relationship with the overhead costs being allocated. For instance, if a company’s indirect costs like utilities and depreciation are heavily influenced by how long machines run, then machine hours would be a suitable choice. Finally, the business must estimate the total quantity of the chosen activity base for the upcoming period. For example, if direct labor hours are chosen, the total number of hours expected to be worked by direct laborers during the period must be estimated. The predetermined overhead rate is an estimated rate calculated before an accounting period begins.